Still requires a metal mold which costs about 10K per part. Regardless what Ween was thinking, a resin piece is the only way to contain costs on a low run item. Make no mistake, anything less than 5,000 pieces is considered low run. WalMart can sell rotocast figures for $14 because they order 50,000+ units. With that kind of production numbers, cost amortization of the tooling becomes almost a non-issue.

Let's just say that SS wanted to make the fridge out of rotocast plastic, and the three-part tooling came in at $15,000.00US (conservative est.) That's $30 per unit on a 500 piece run, and you haven't even cracked open a container of plastic to inject into the mold.

It would shock you to know how little the "polystone" pieces we prize so much actually cost to produce. Most of the cost is tied up in licensing and a healthy profit margin for the company.

Fact: A "coldcast porcelain" statue I worked on for another well-known collectibles company cost $8.00US per unit to cast, paint, package, and ship from China. That was a numbered collectible, with a limited edition of 1,500 pieces. Retail was $75.00US.

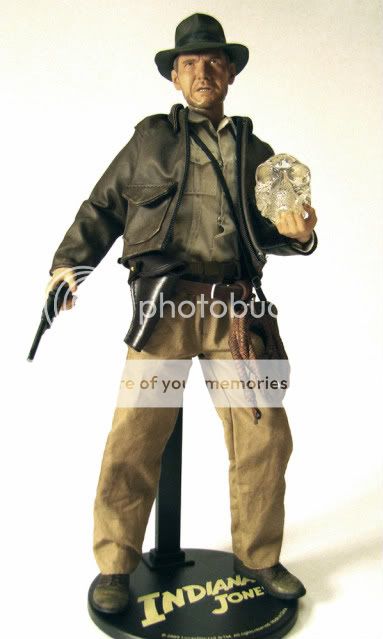

Excellent point. I wouldn't have batted an eye for $125. But $175 was simply too much for me, as big an Indy fan as I am.

Excellent point. I wouldn't have batted an eye for $125. But $175 was simply too much for me, as big an Indy fan as I am.

No drop shipping. And if we upped it to $35 a unit, yes, they could paint and package. As with Sideshow (who doesn't drop ship - I don't know where you got the idea that they do), they'll box them up and send them on a freighter across the Pacific.

No drop shipping. And if we upped it to $35 a unit, yes, they could paint and package. As with Sideshow (who doesn't drop ship - I don't know where you got the idea that they do), they'll box them up and send them on a freighter across the Pacific.