Amazing...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/6 Scale Blade Runner Spinner scratchbuild (Complete!)

- Thread starter Marine Boy

- Start date

Help Support Collector Freaks Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Marine Boy

Super Freak

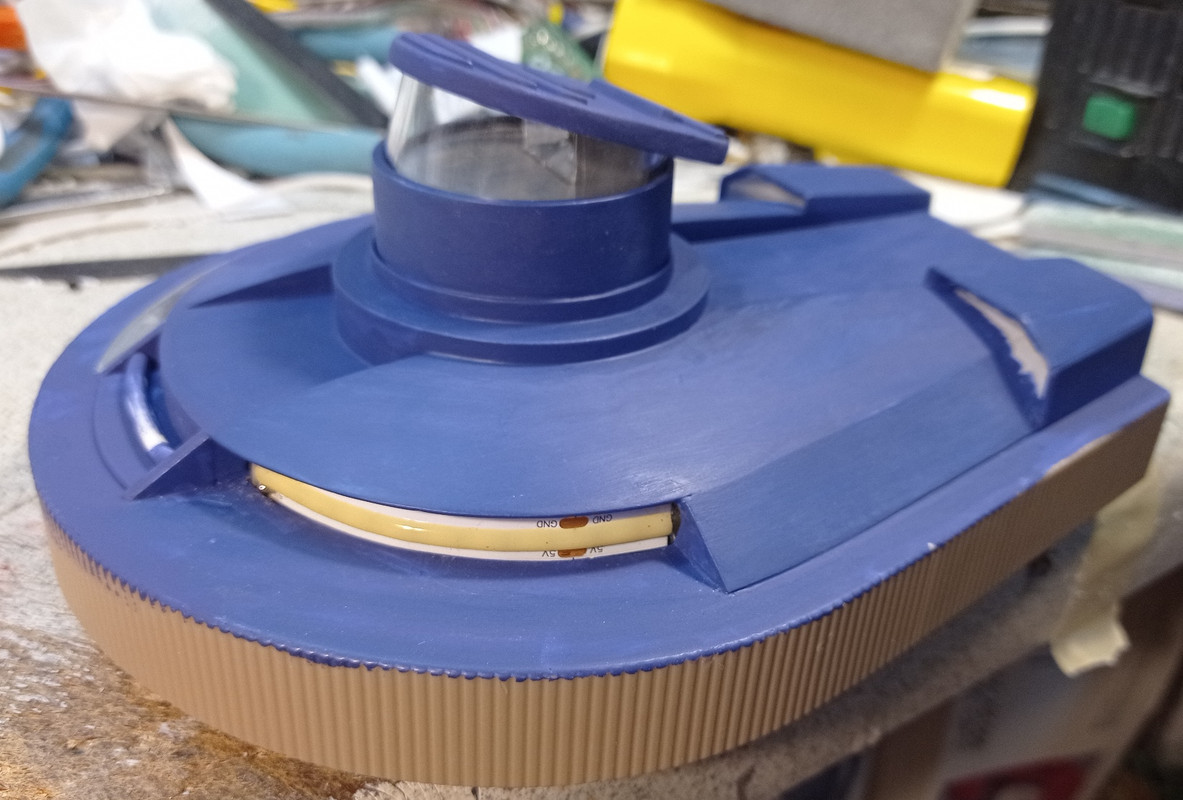

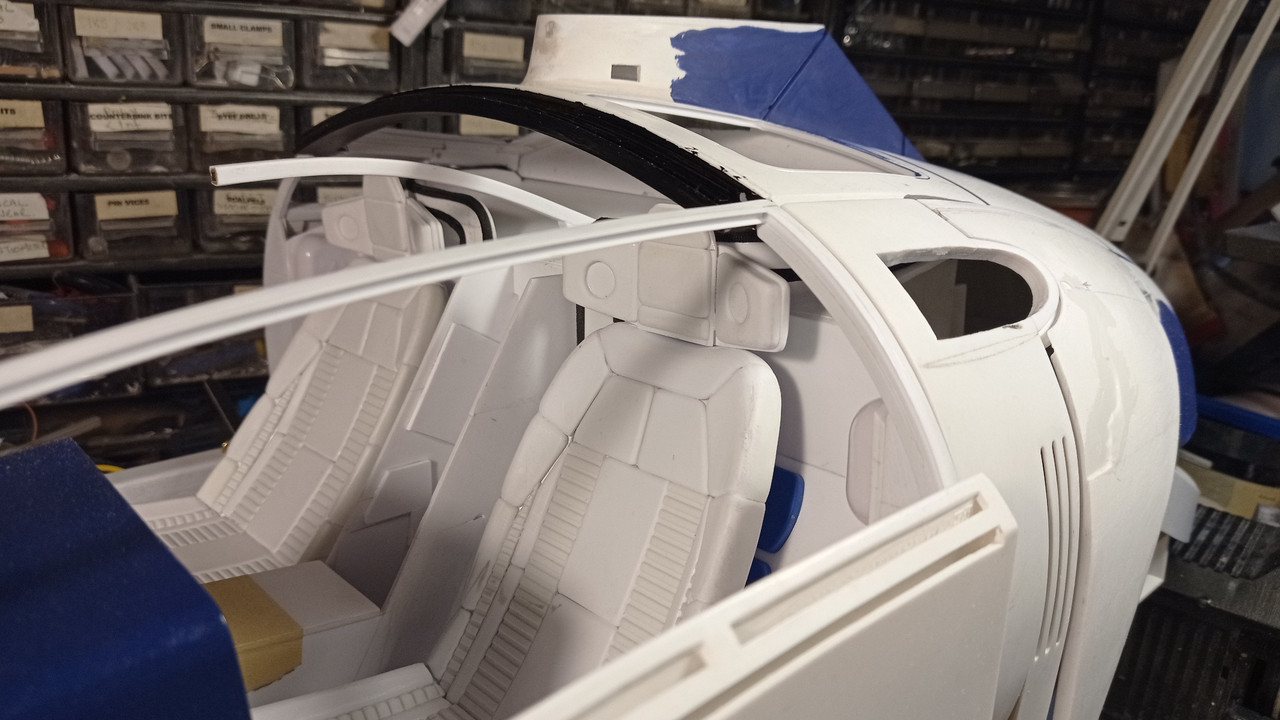

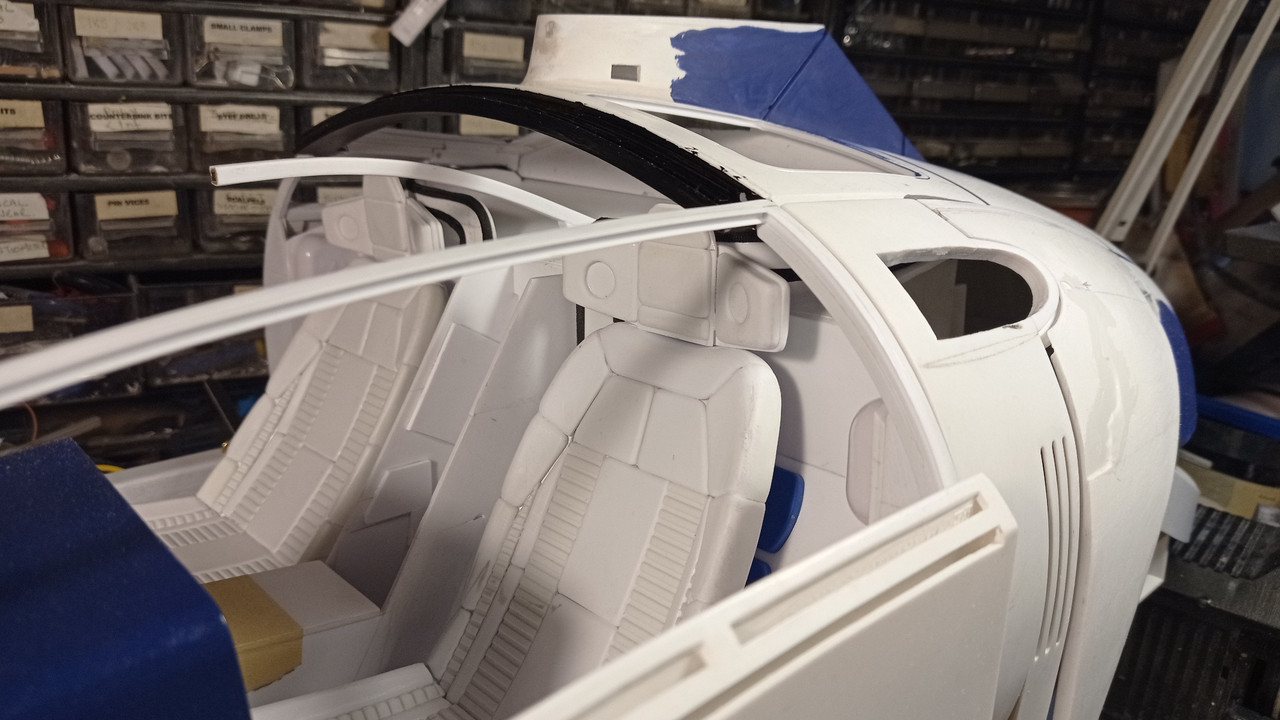

Attaching the wheel covers. There's still some work to be done to align all the panel edges. I was going to keep the rear bodywork separate, to access the batteries, but gluing it to the roof, allowed me to smooth the panels together, more easily.

Battery access will be through the wheel covers. These are meant to double as wings during high speed flight.

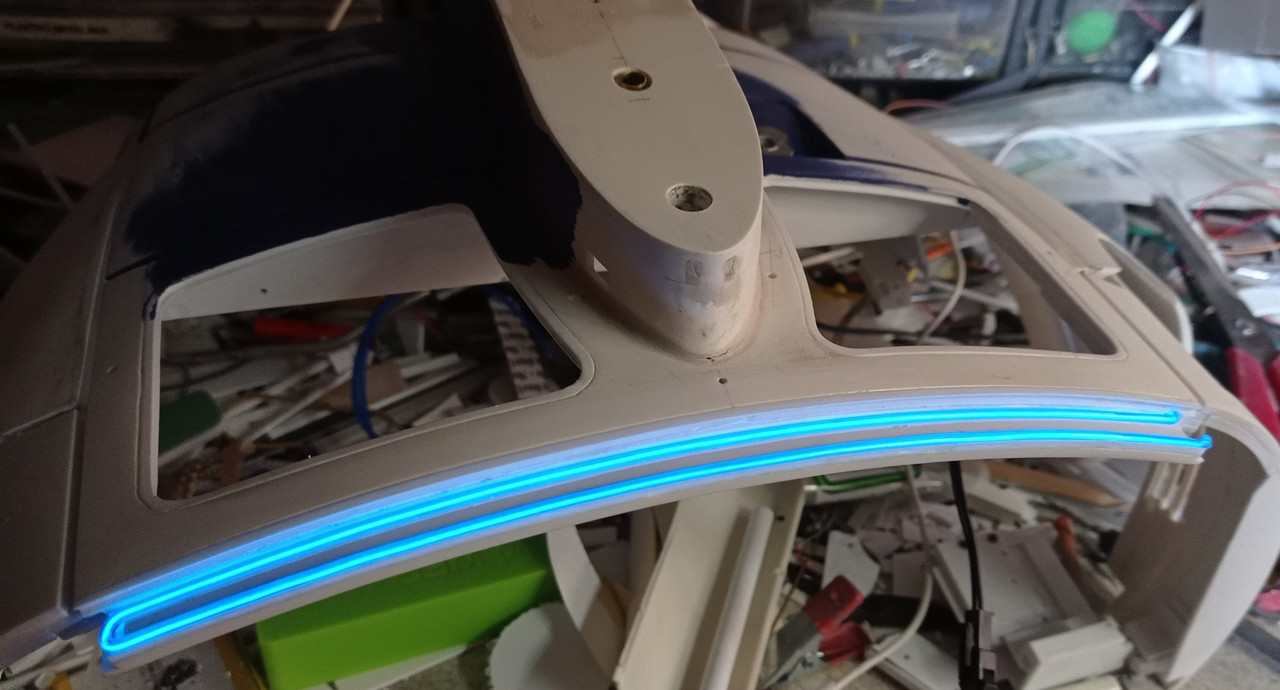

Fitting LED strips to the front wheel covers. The glass panels just push in.

Battery access will be through the wheel covers. These are meant to double as wings during high speed flight.

Fitting LED strips to the front wheel covers. The glass panels just push in.

Marine Boy

Super Freak

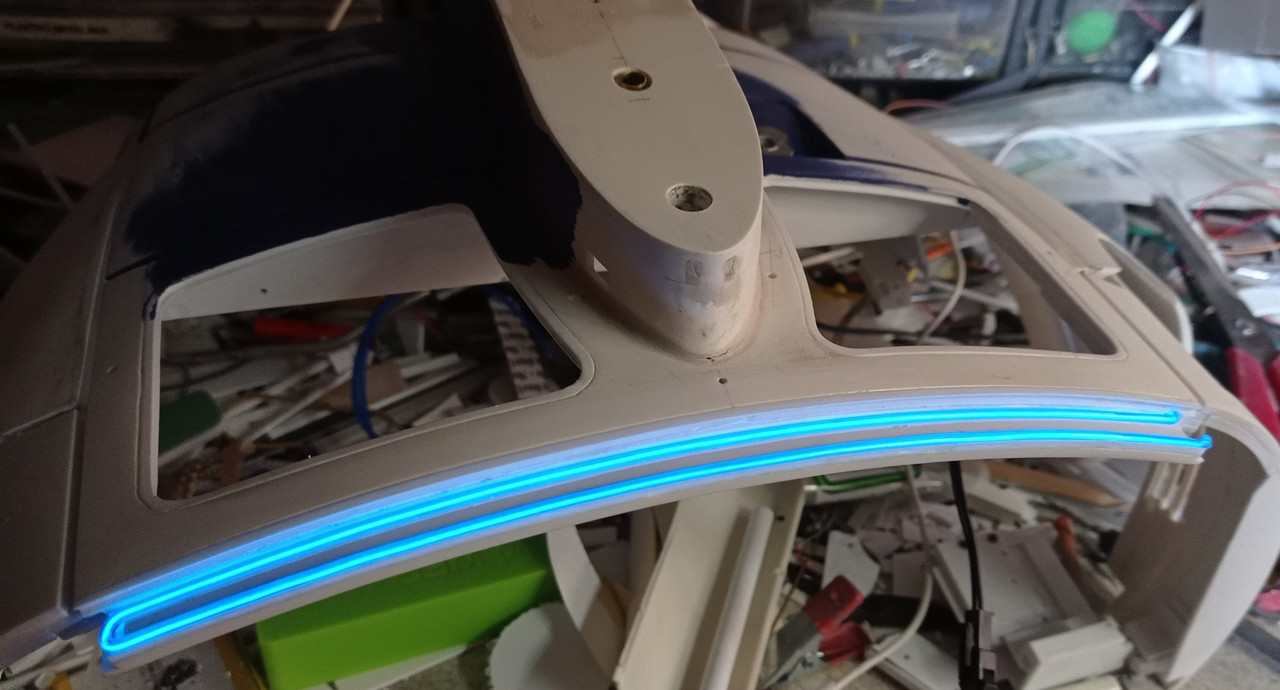

Building the channels needed for the EL wire.

EL wire installed temporarily. They will be glued in after painting is complete.

Building the oval side windows. It is taking a long time to match all the curved surfaces.

EL wire installed temporarily. They will be glued in after painting is complete.

Building the oval side windows. It is taking a long time to match all the curved surfaces.

Marine Boy

Super Freak

A quick update on the build so far. There is still some chassis flex, so the doors don't fit properly when its on it's wheels. I will reinforce the floor pan some more. Once the glass is in place, that will help too.

EL wire fitted to the interior parts.

EL wire fitted to the interior parts.

Marine Boy

Super Freak

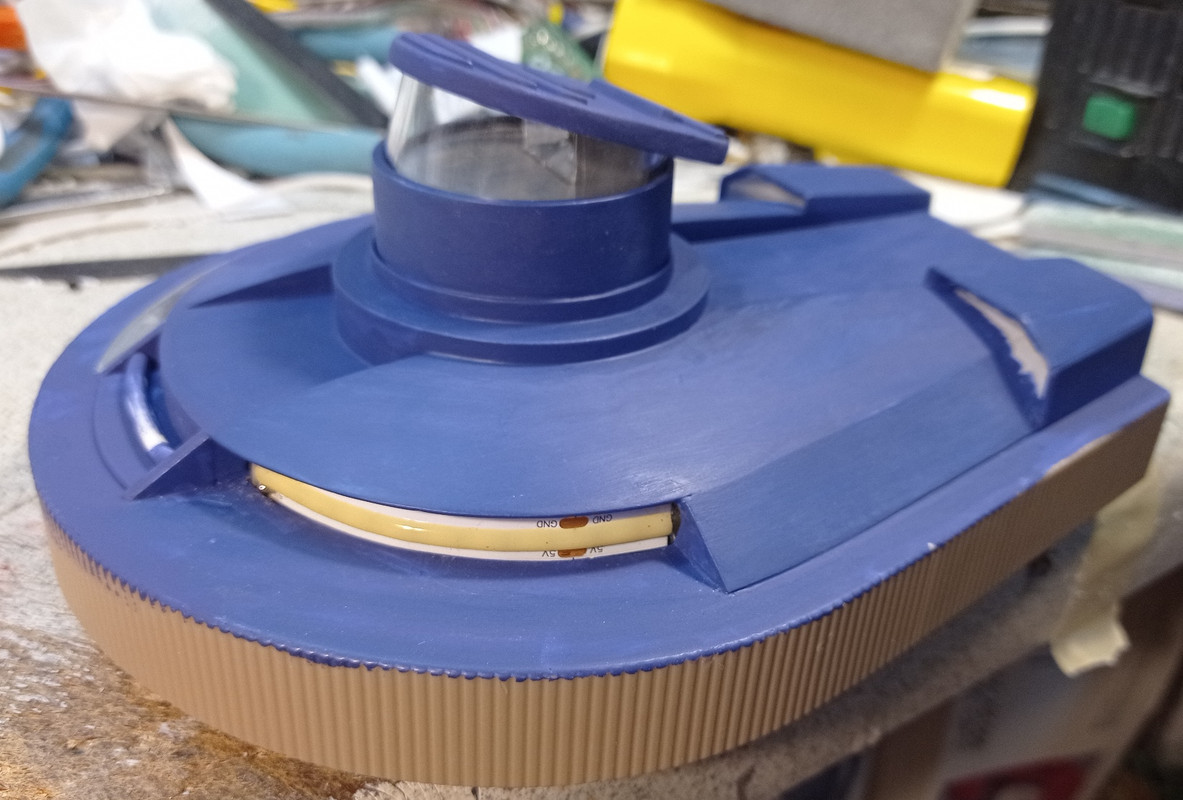

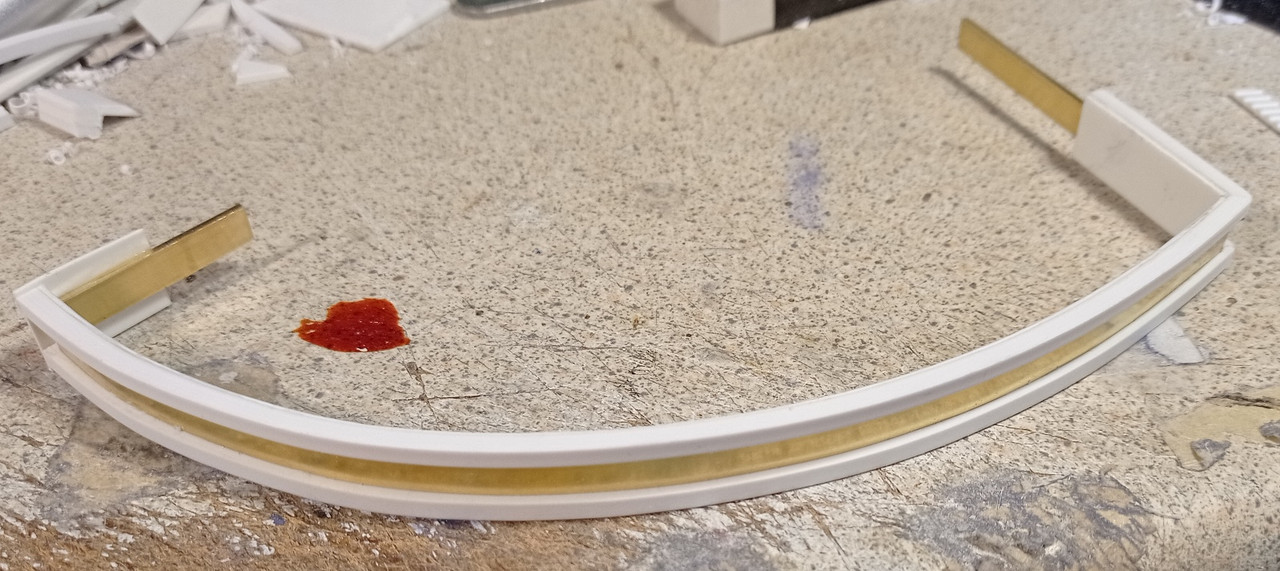

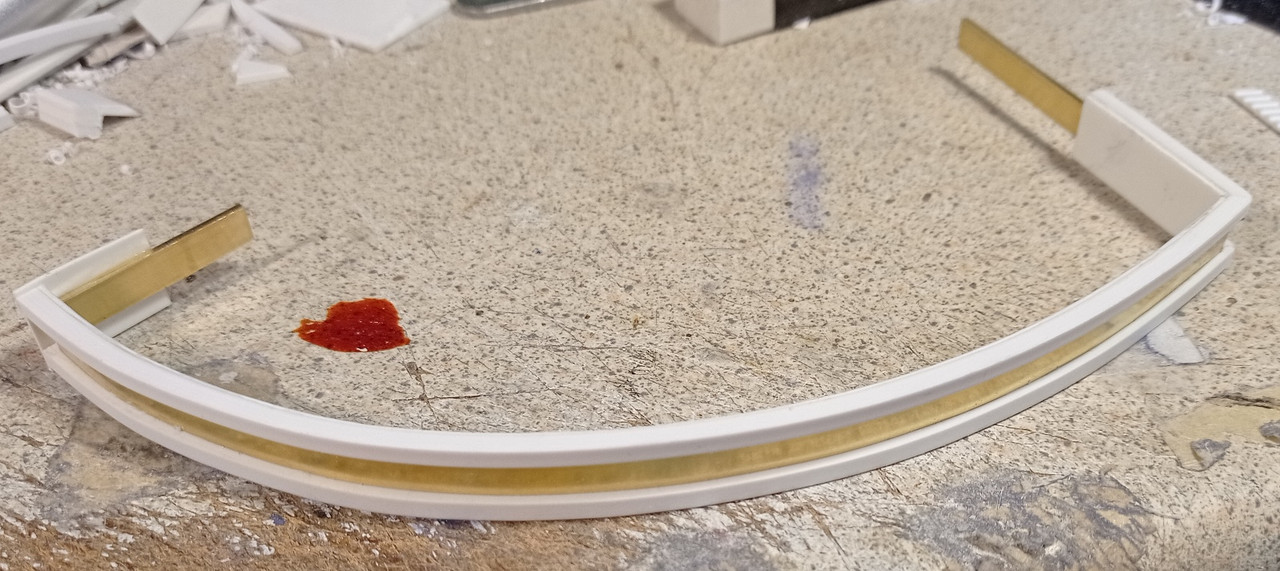

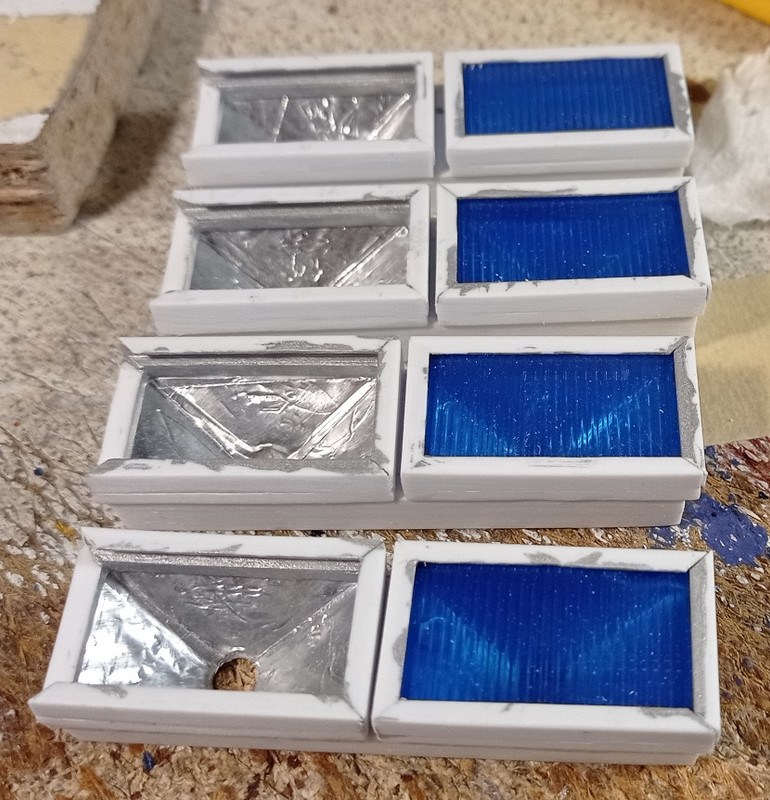

Fitting EL panels to the wheel covers.

Unfortunately, I'll have to redo the yellow panel. The EL sheet is quite fragile. I tried to trim the edge down with a scalpel which was a mistake. It's better to cut with scissors, as it applies pressure on both sides. The scalpel only puts pressure from one side, causing the layers to separate, giving that messy edge. Done properly, it gives a nice even glow.

Unfortunately, I'll have to redo the yellow panel. The EL sheet is quite fragile. I tried to trim the edge down with a scalpel which was a mistake. It's better to cut with scissors, as it applies pressure on both sides. The scalpel only puts pressure from one side, causing the layers to separate, giving that messy edge. Done properly, it gives a nice even glow.

$10.99

$14.99

DC Comics, 12-Inch Superman Action Figure, Collectible Kids Toys for Boys and Girls

Amazon.com

Marine Boy

Super Freak

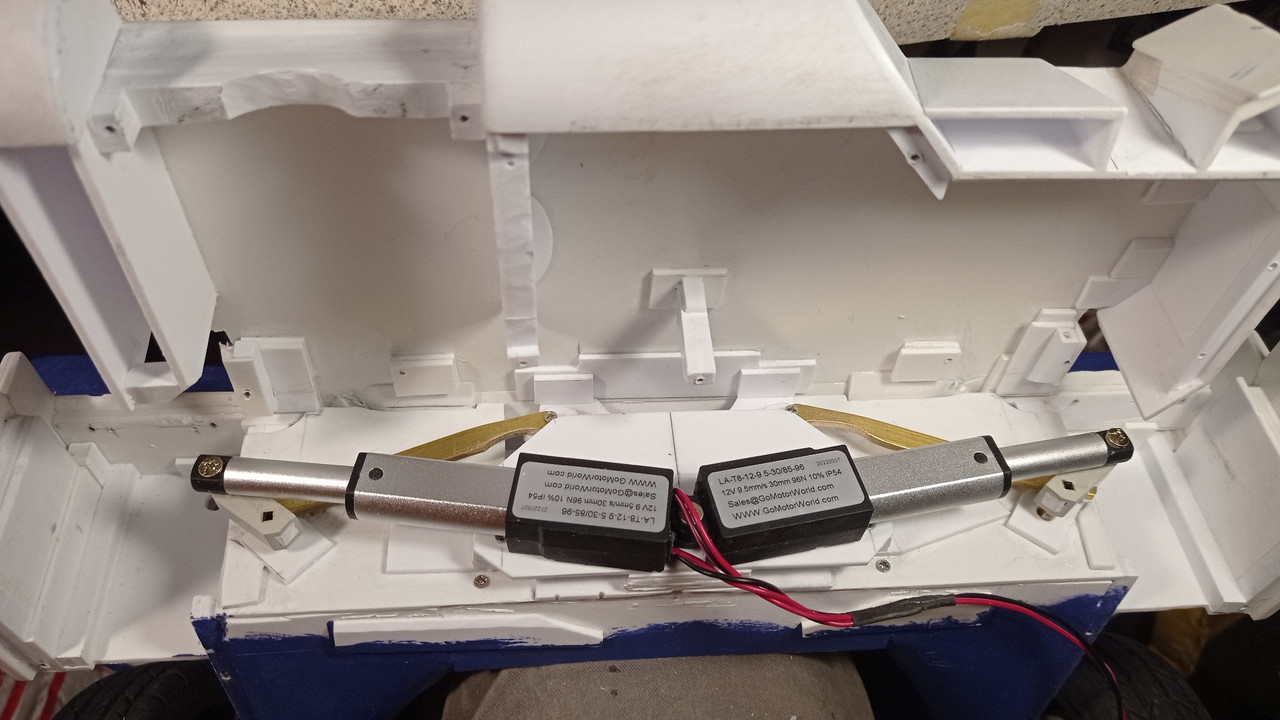

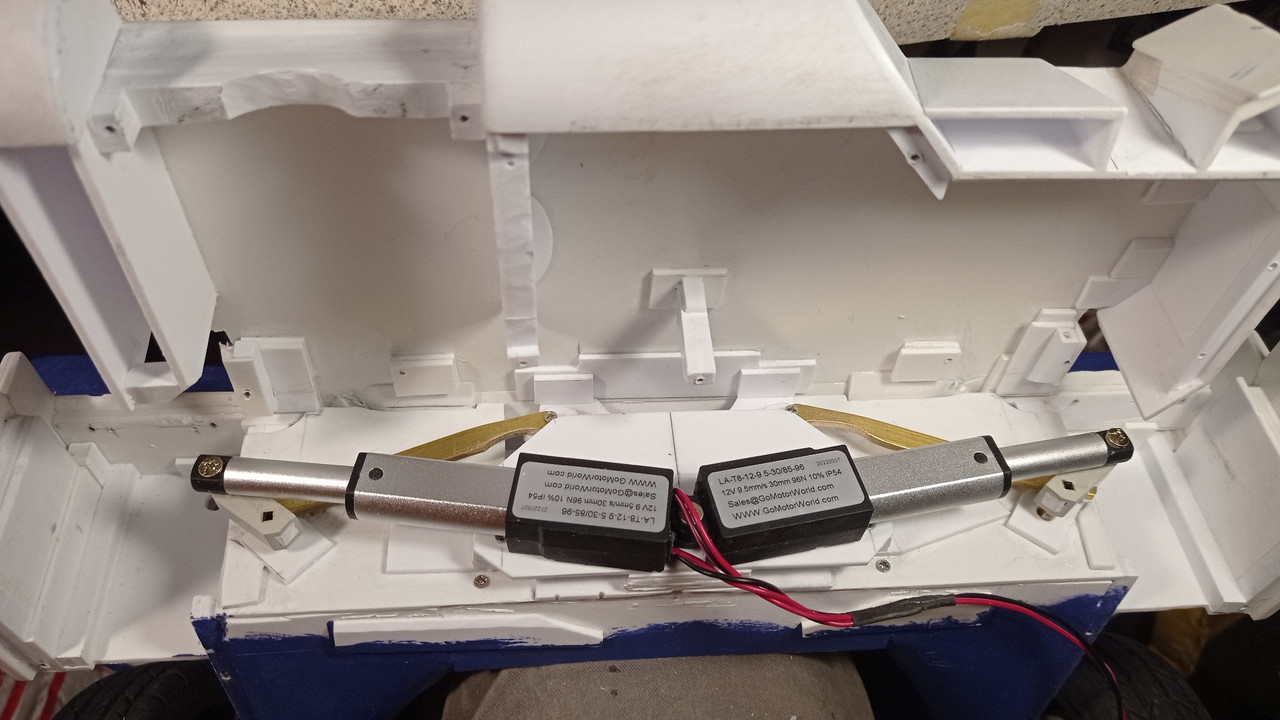

I had to tweak the front wheels yet again. Even though the actuators are exactly the same, there were times they would open at different rates, which looked odd. I had to refit the gears (hidden behind panel) to physically link each side together.

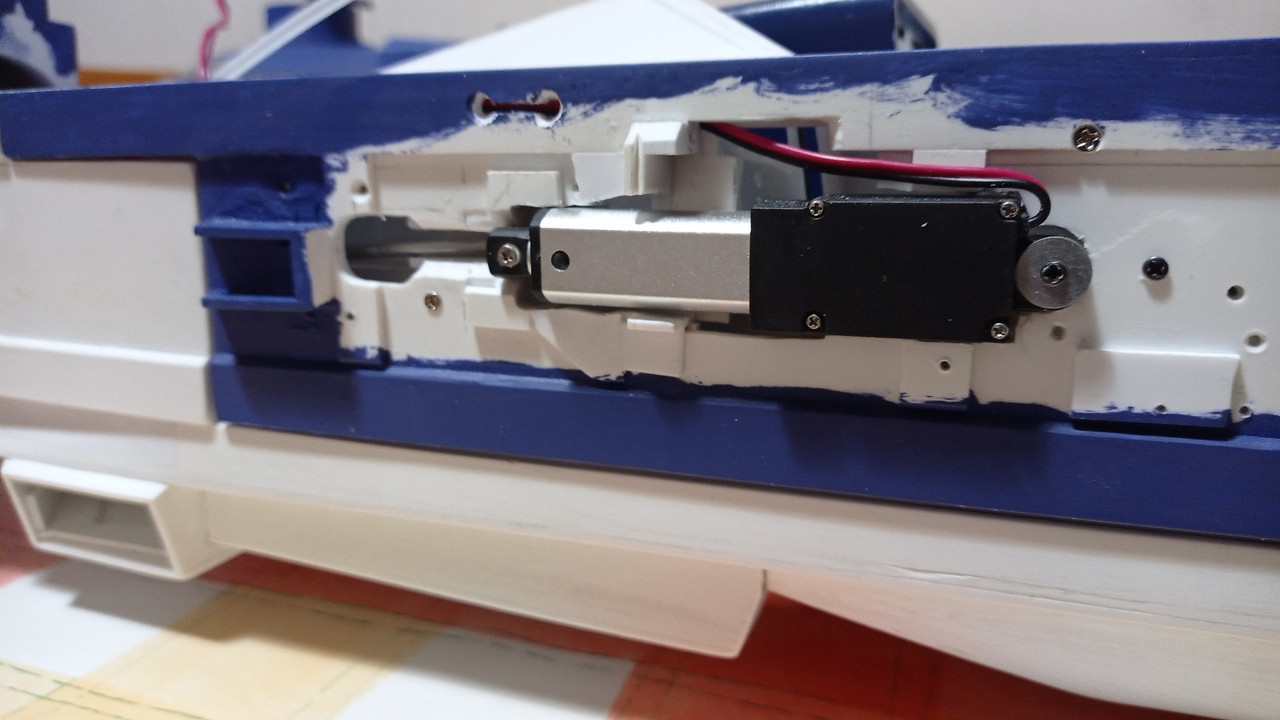

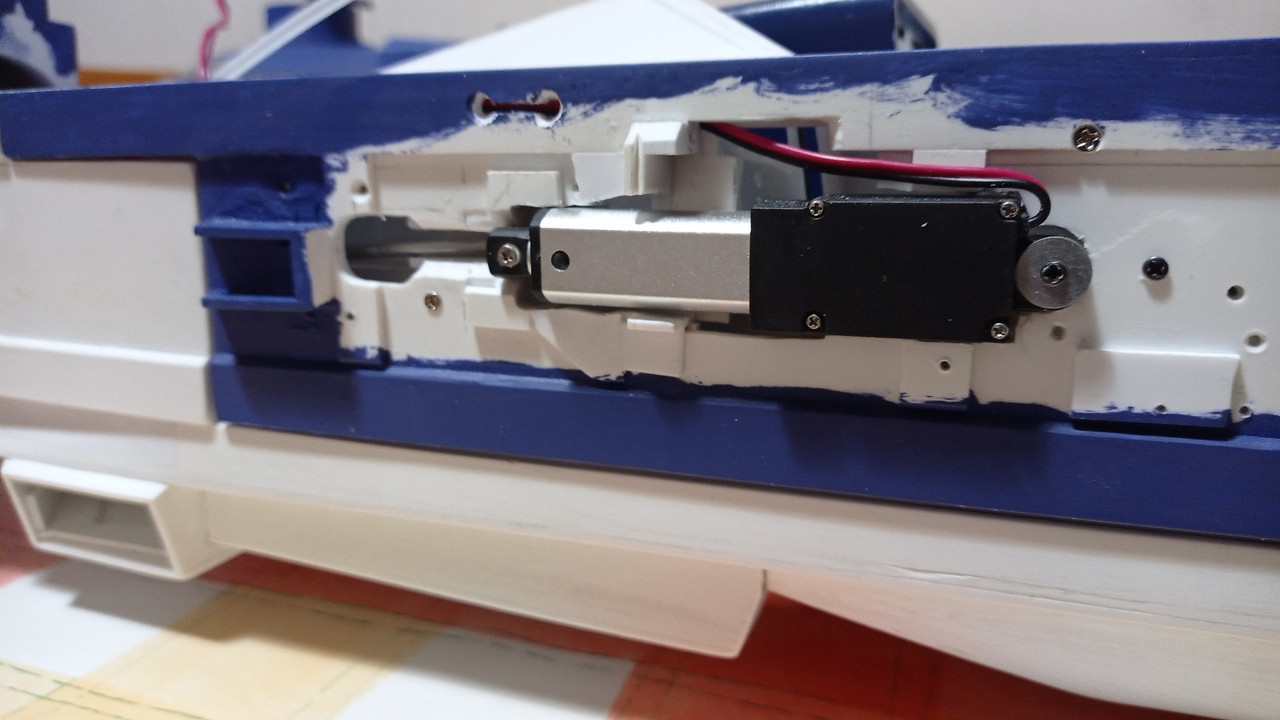

I fitted more linear actuators to both doors. I wanted to avoid this, as they cost £25 each, but they are much quieter and smoother now.

A little bit of adjustment required, as the maximum opening angles are slightly different.

I had to tweak all of the linkages for the wheel covers. Before. with the covers closed, they would move out of position, with all the weight of the front end pushing them up, Much better now.

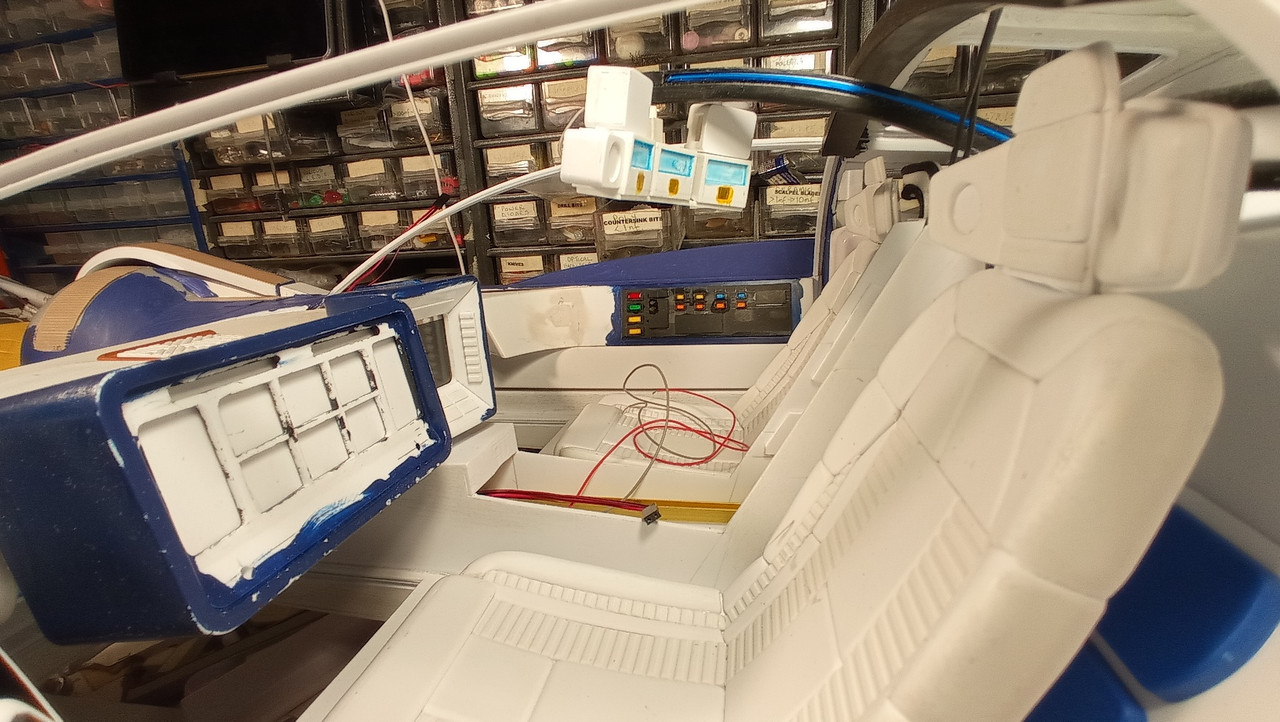

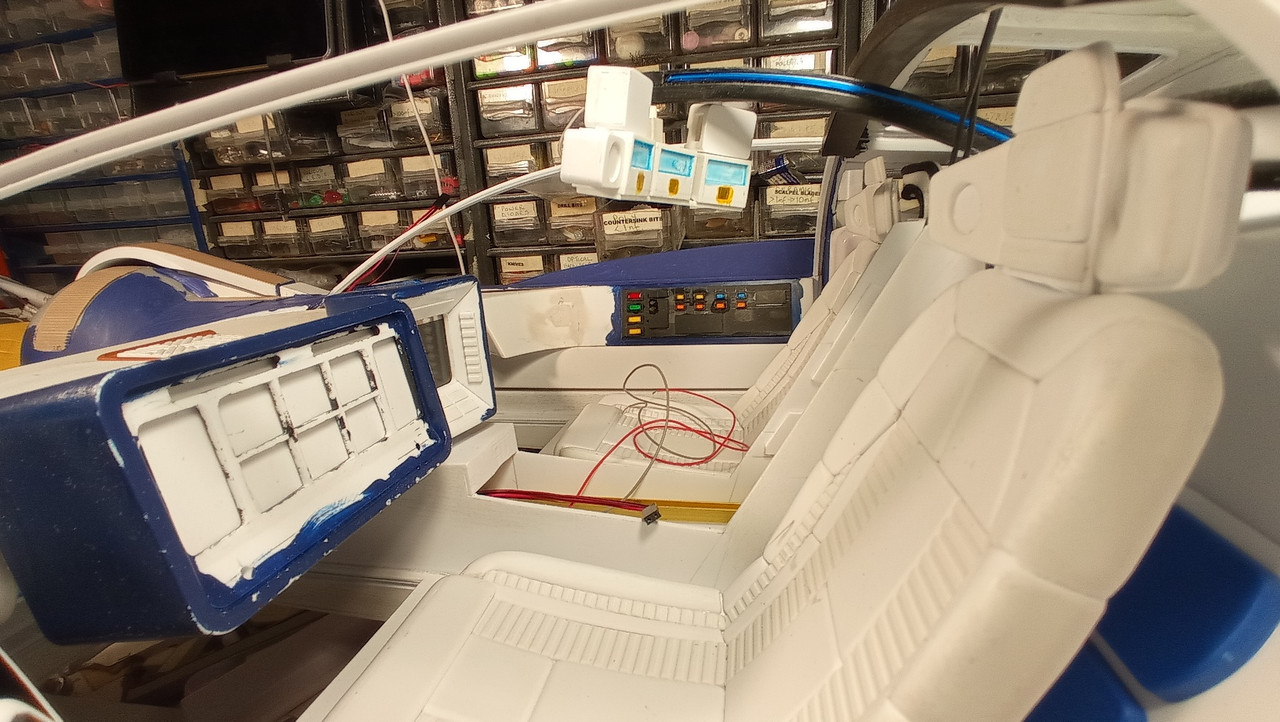

I'm going to move the instrument binnacle forward slightly, so there is more room for the controls. You can just see the metal beams added to the central spine, to stop the chassis flexing too much.

Door test

I fitted more linear actuators to both doors. I wanted to avoid this, as they cost £25 each, but they are much quieter and smoother now.

A little bit of adjustment required, as the maximum opening angles are slightly different.

I had to tweak all of the linkages for the wheel covers. Before. with the covers closed, they would move out of position, with all the weight of the front end pushing them up, Much better now.

I'm going to move the instrument binnacle forward slightly, so there is more room for the controls. You can just see the metal beams added to the central spine, to stop the chassis flexing too much.

Door test

Marine Boy

Super Freak

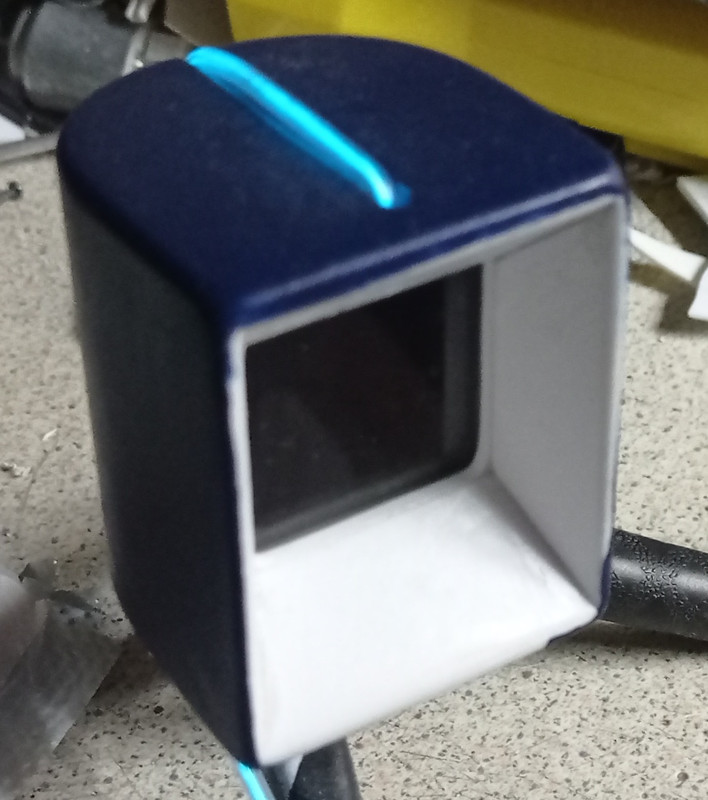

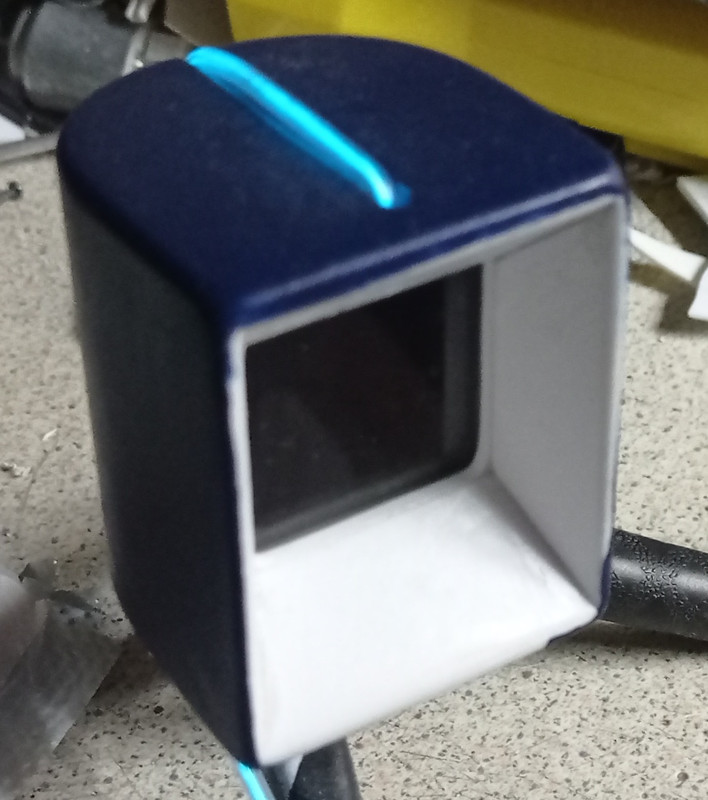

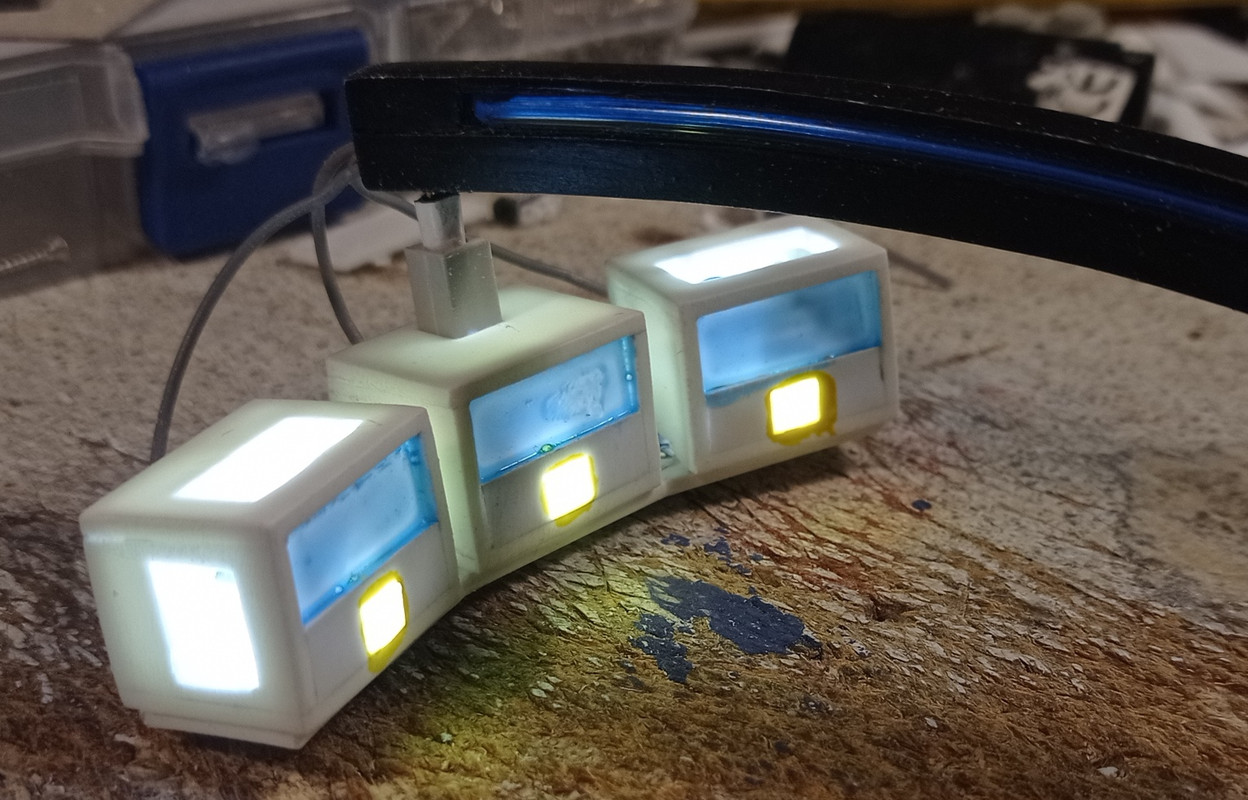

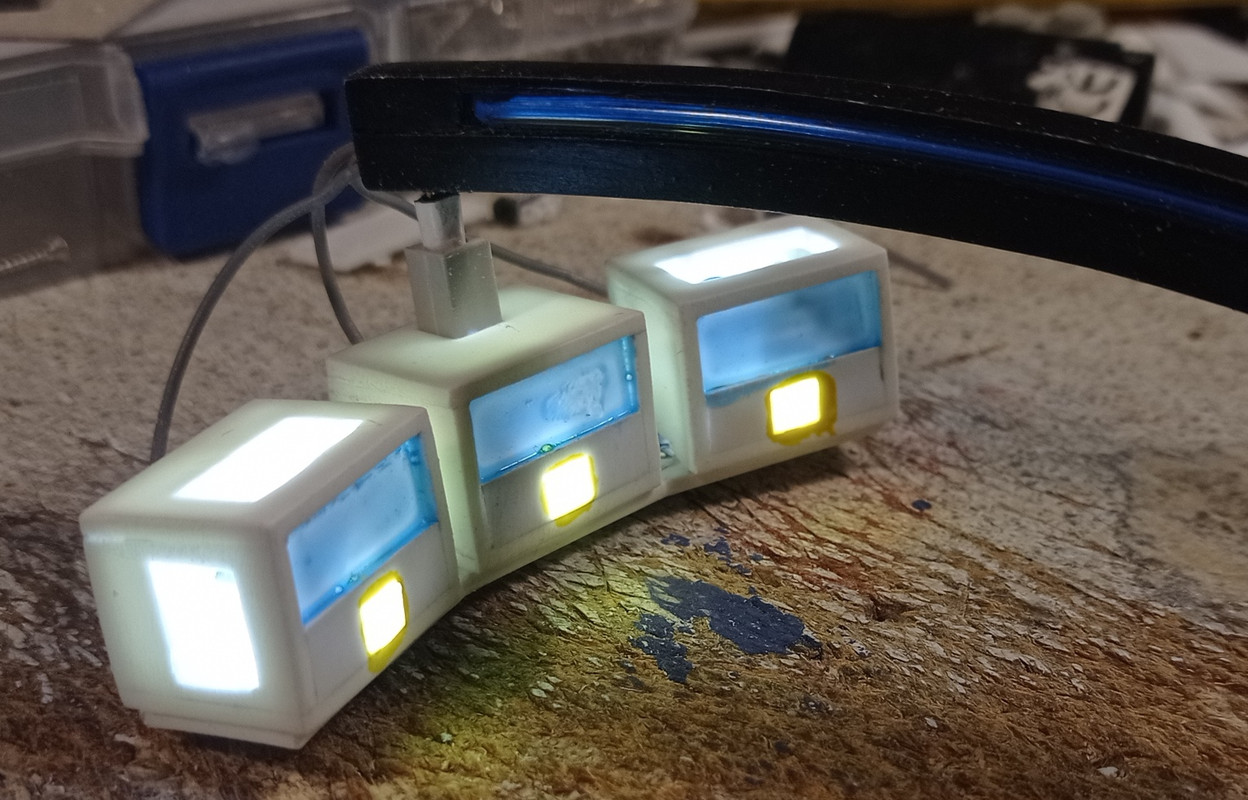

Making the overhead displays. The openings are to allow light to pass into the outer clocks.

Space Jockey

Super Freak

This is coming along very well. Excellent work!

Marine Boy

Super Freak

Building the side windows. These took much longer than expected, because cutting such large openings into the side panels made them very weak. As they are the main supports for the roof, they had to be reinforced.

Marine Boy

Super Freak

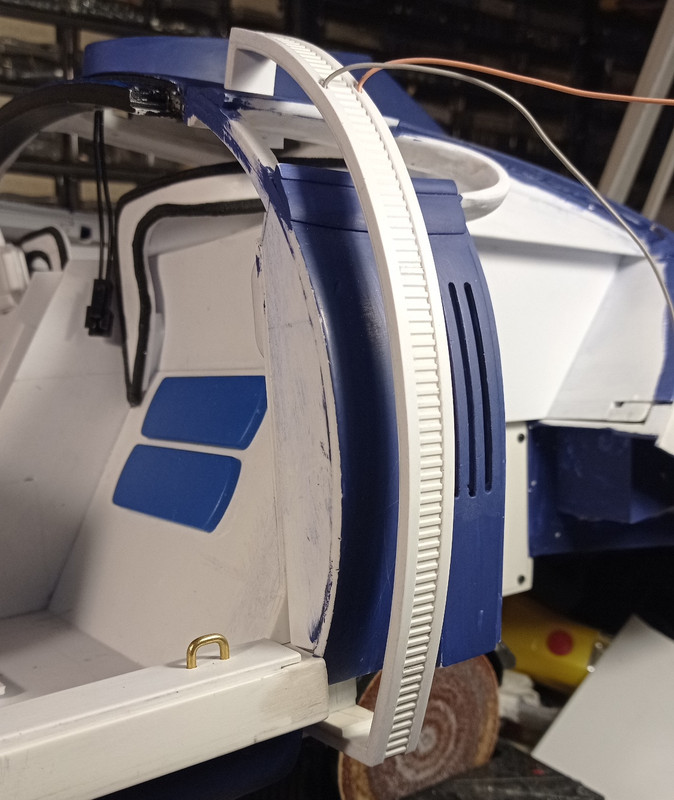

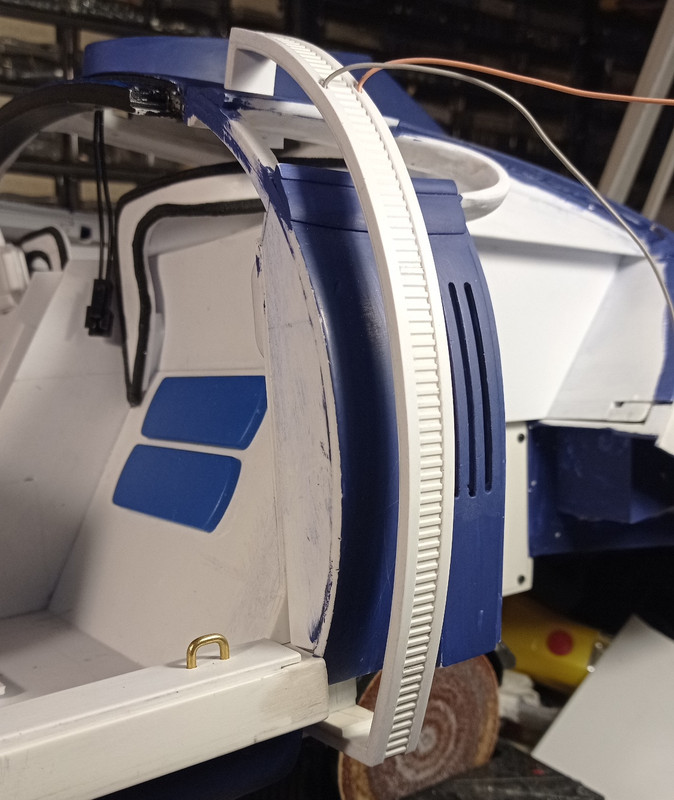

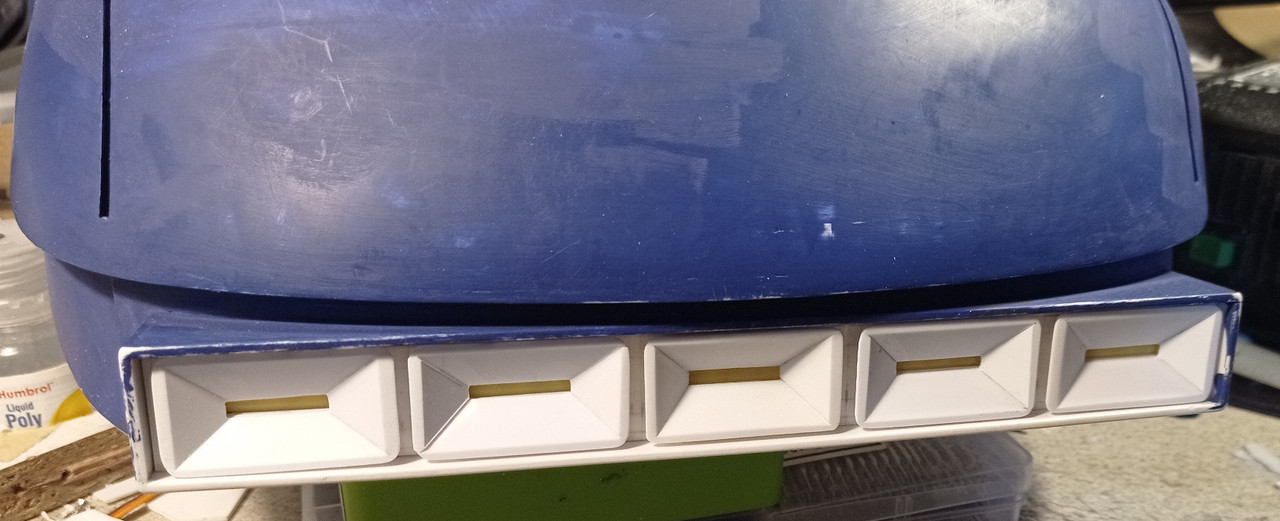

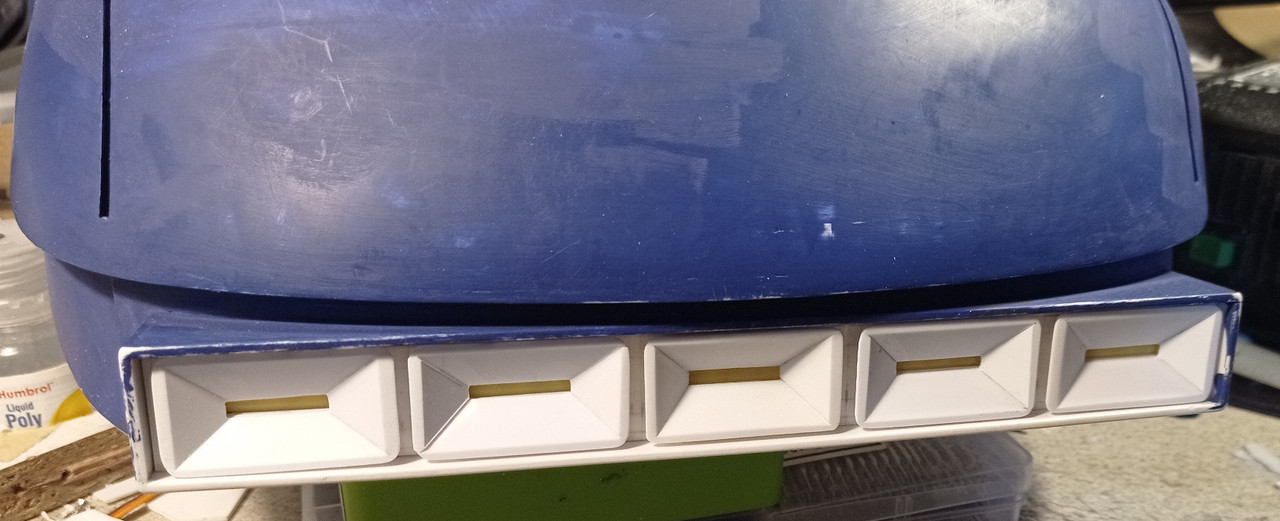

Making the rail on the driver's side. There is a brass flat bar inside for strength.

Mounted to the bodywork. The rail should curve under at the bottom, rather than an angle, so i'll have to redo that section later.

Light fitting under construction.

Mounted to the bodywork. The rail should curve under at the bottom, rather than an angle, so i'll have to redo that section later.

Light fitting under construction.

Marine Boy

Super Freak

Reworked the lower part of the rail. I fitted a temporary light beacon for now. I will have a new one vacformed when i get the glass made.

Marine Boy

Super Freak

Finished making the rear nozzles. I've fitted a microswitch to the rear suspension, so that the lights come on, when the car is lifted off the ground.

I will paint the back to stop light leakage between the nozzles.

I will paint the back to stop light leakage between the nozzles.

Marine Boy

Super Freak

Dash display printed onto paper and stuck onto a thin sheet of plasticard. I retouched the black areas with paint to increase the contrast.

Making the centre console with functional switches. The blue buttons are for the instrument lighting and the night time lighting.

Making the centre console with functional switches. The blue buttons are for the instrument lighting and the night time lighting.

Marine Boy

Super Freak

More work done to the centre console.

I'm also taking advantage of the sunny weather in the UK right now and getting all the main body panels spray painted.

I'm also taking advantage of the sunny weather in the UK right now and getting all the main body panels spray painted.

Marine Boy

Super Freak

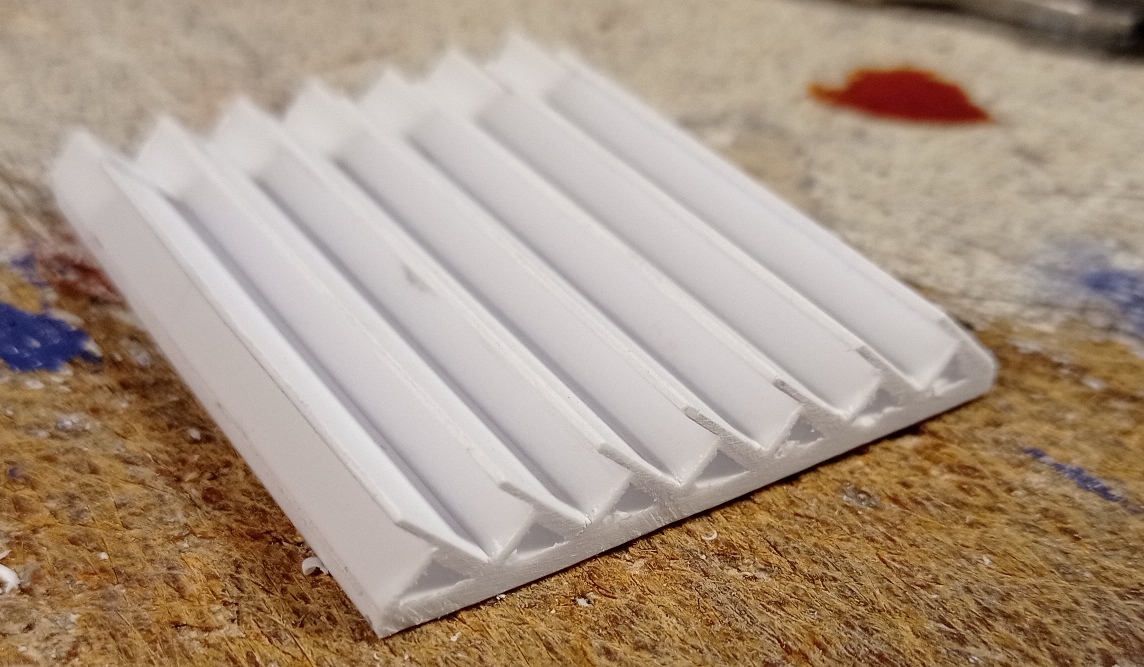

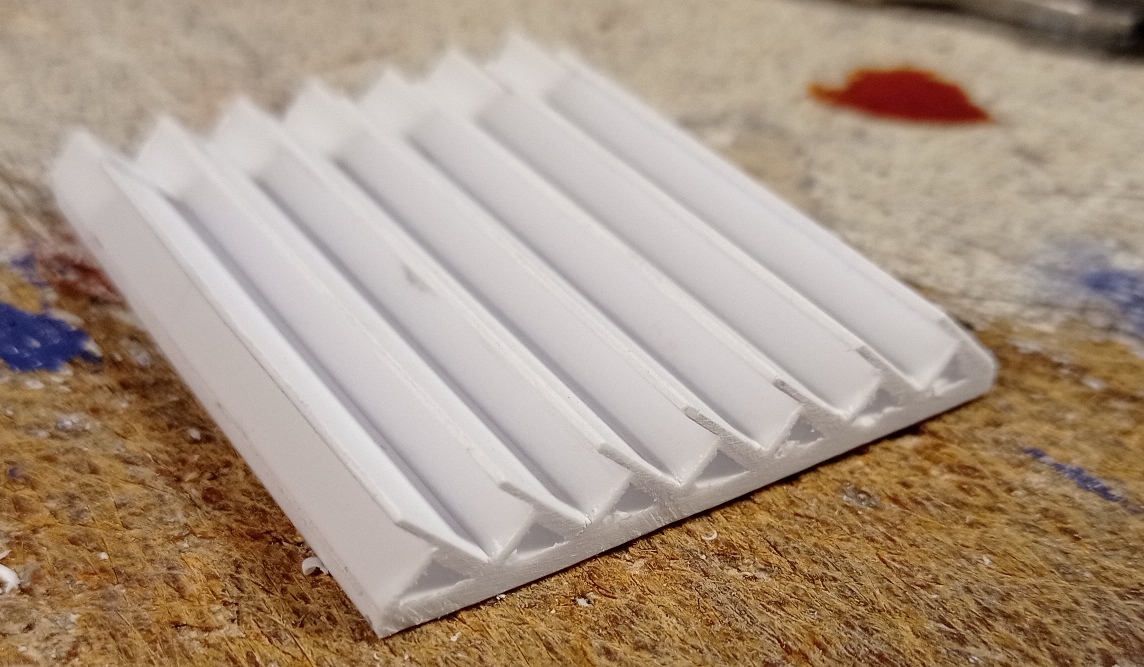

Building the thruster nozzles. I started by gluing some "L" beams onto a sheet of plasticard. Add some flat strips on top to give more depth.

Cut out the panel to the required size and drill out the vents, front and back.

Cut out the slots with a knife and paint.

Building the light enclosure. There is a very thin sheet of plasticard behind the vents to diffuse the light.

Installed into the housings.

These will light automatically, when the car is lifted off the ground.

Cut out the panel to the required size and drill out the vents, front and back.

Cut out the slots with a knife and paint.

Building the light enclosure. There is a very thin sheet of plasticard behind the vents to diffuse the light.

Installed into the housings.

These will light automatically, when the car is lifted off the ground.

Crazy amount of detail you put into your builds.

This is just beyond words. What a remarkable piece of art you are building. Thank you for sharing.

Marine Boy

Super Freak

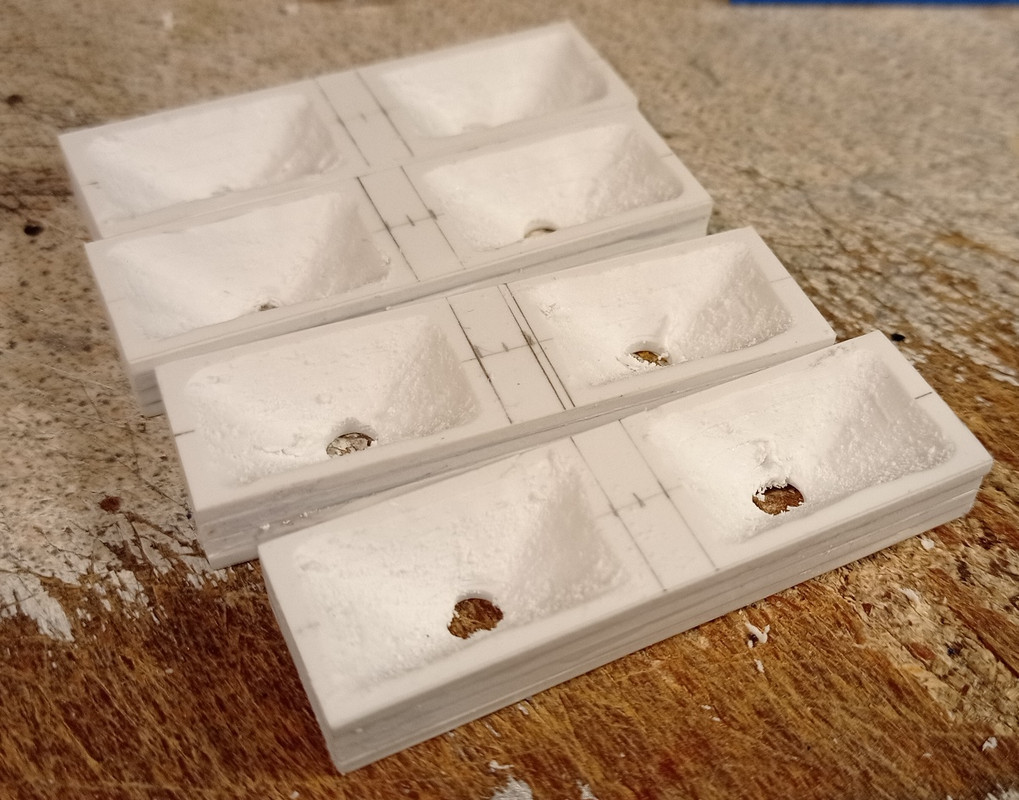

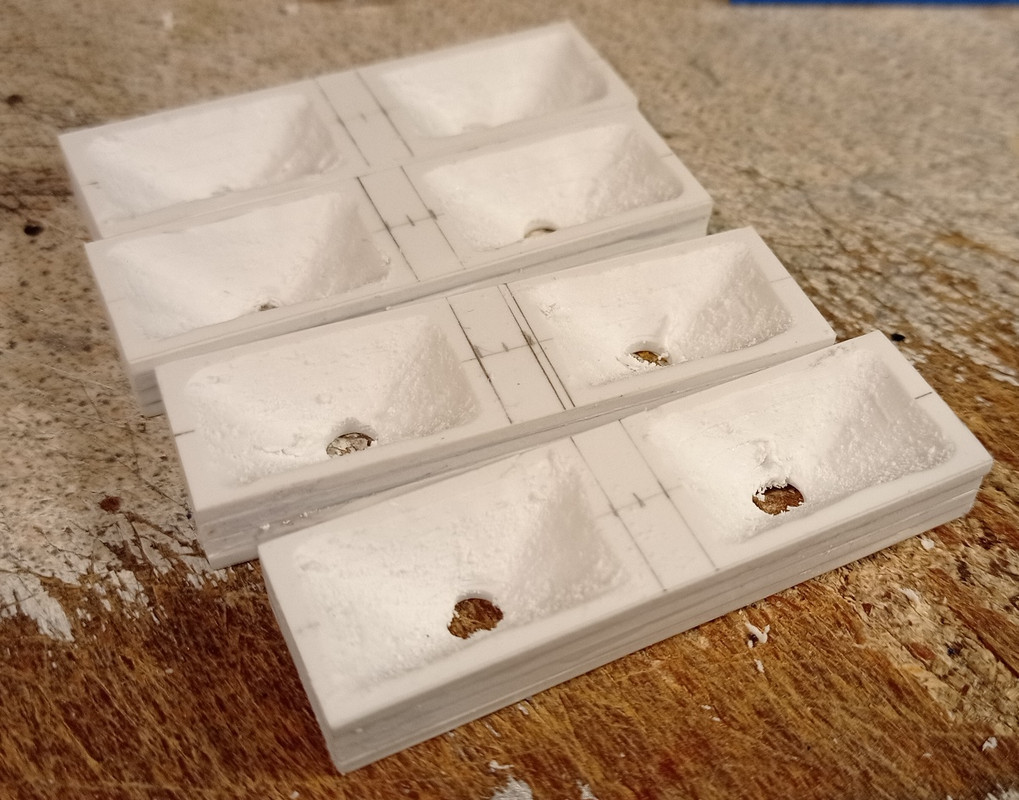

Making the underbody strobe lights. I started by gluing some "U" channel to a frame.

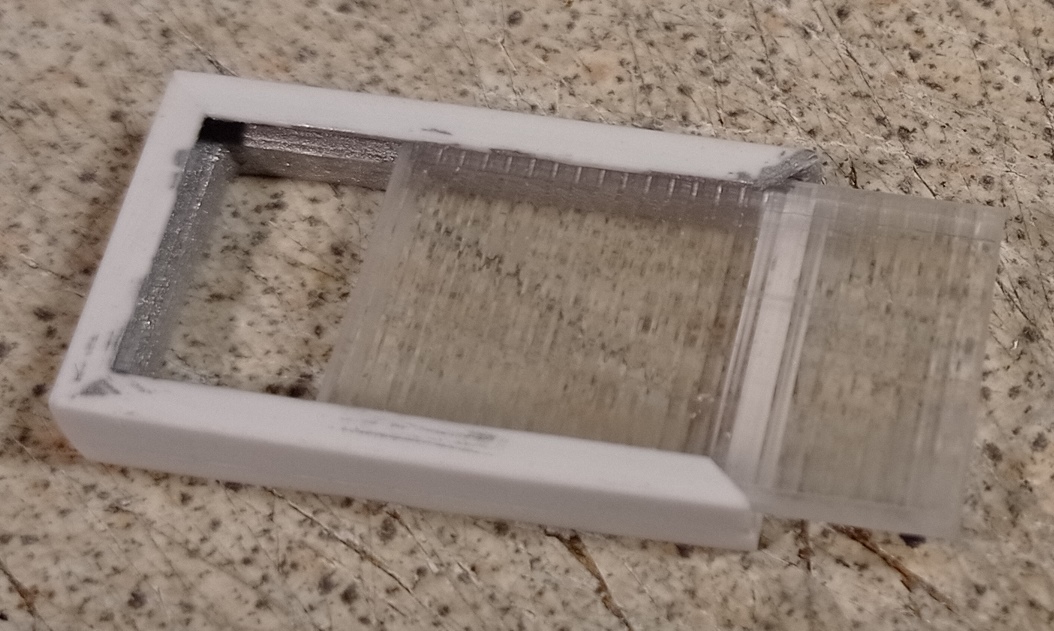

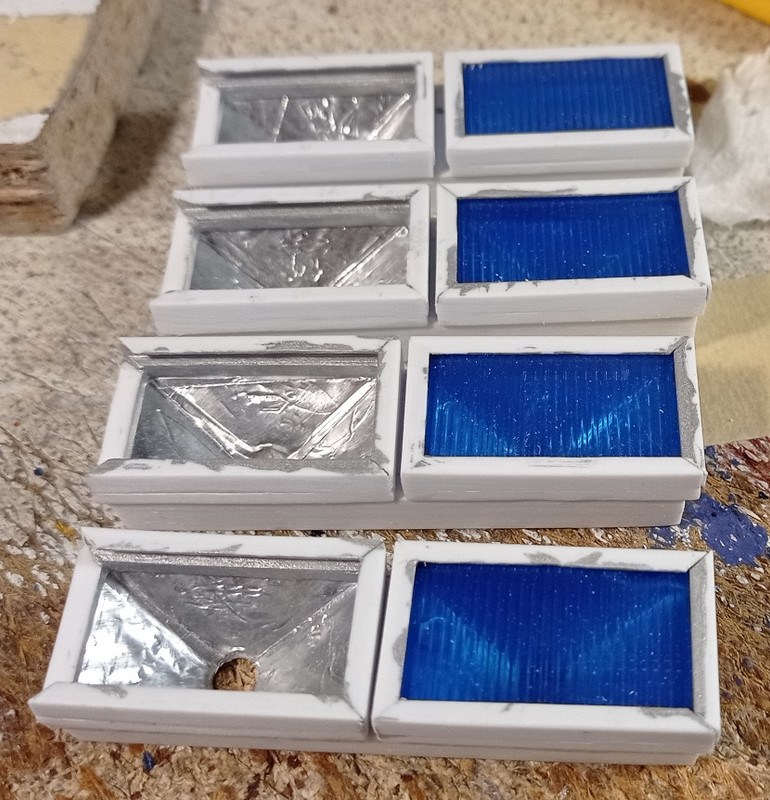

A clear ridged light panel is slid into place. This was cut from a cassette case. (remember those?)

The mounts start out as plasticard strips glued into blocks.

Drill 2 5mm holes for the LEDs.

Shape the reflectors using a dremel and finesse with a knife.

Apply some chrome tape.

Glue the frames on top.

Paint and fit the light panels. Another section of channel is glued to secure it. I will make the red lenses, as soon as i can find another cassette box.

Light test

Attached to the floorpan with screws.

A clear ridged light panel is slid into place. This was cut from a cassette case. (remember those?)

The mounts start out as plasticard strips glued into blocks.

Drill 2 5mm holes for the LEDs.

Shape the reflectors using a dremel and finesse with a knife.

Apply some chrome tape.

Glue the frames on top.

Paint and fit the light panels. Another section of channel is glued to secure it. I will make the red lenses, as soon as i can find another cassette box.

Light test

Attached to the floorpan with screws.

Space Jockey

Super Freak

Okay, explain yourself, lol! You must have worked in the effects industry at some point. Really stellar work, and I'm grateful for your informative posts, very interesting.

Similar threads

- Replies

- 307

- Views

- 15K

- Replies

- 13

- Views

- 4K

Latest posts

-

Asmus Toys: Escape From New York Snake Plissken

- Latest: Chopper Face

-

-

-

-

Asmus Toys: Gil-Galad 1/6th action figure

- Latest: master anakin skywalker

-