kyloblack

Freakzoid

this is insane!!! amazing work

) and possibly Maxx-replicas.

) and possibly Maxx-replicas.

Very nice ����

Hey Izzy. Any chance I could still get the STL file for the 1/6 Tattooine vaporator box?

Yes. Need your email.

Pm’d contact... thanks!

Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

Untitled by Izzy Mel, on Flickr Untitled by Izzy Mel, on Flickr

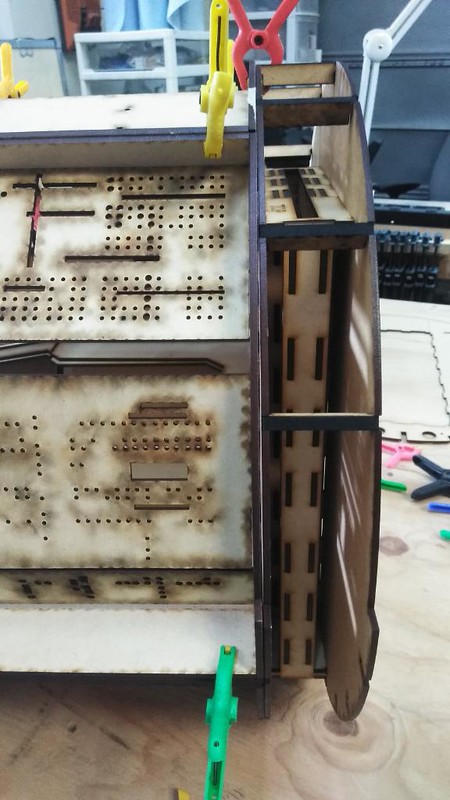

Untitled by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on Flickr YT 1300 framework by Izzy Mel, on Flickr

YT 1300 framework by Izzy Mel, on FlickrQuick update on the YT-1300:

Here are some more of the 3d renderings of the cockpit greeblies I made for the 1/6 YT 1300 cockpit. I still have to print them with the Any Cubic Photon resin printer. Its a start and many more to follow:

Absolutely stunning IzzyMel!!

Besides that, I am considering purchasing a 3D printer, partiallly because of threads like this one or yours! It is quite an investment, and right now I can't think about any life-and-death problems I would be able to solve with this particular piece of machinery, but I think that once I own it, applications will all of a sudden start to pop up all over the place (and yeah, I have a little money burning in my pocket!!).

Could you please tell us a bit more about your 3D printer?

Any reasons (besides lower price) that made you choose that brand instead of others like e.g. formlabs.com?

Don't you find the Photon's inferior printing volume too limiting?

Just how expensive is this whole 3D-printing issue as regards resin liquid?

I understand there is a pre-print processing that has to be done on the 3D model via some proprietary SW so that printing succeeds. Is it very constraining? Does it make it feasible to print several pieces in one run (distributed across the printing volume) and thus optimize energy/time/resin consumption?

There is also a manual, post-print processing, which entails removing supports, sanding down imperfections, etc? Is it very difficult skill-wise and time consuming?

I understand there is some degree of continuous maintenance to 3D printing, like for instance resin filtering among others. Is it very time consuming?

Finally: just how smooth is the final result? Considering the high 3D resolution, are perfectly smooth, like-molded surfaces even possible?

Thanks a lot for your insight IzzyMel! I hope one day I will be able to imitate your 3D feats!

m.

Thanks,

I have several 3d printers. My work horse is the Raise3D N2. But for small highly detailed pieces I use the Any Cubic Photon. I chose it because of price and I wanted to start with something small before i spent crazy money for a resin printer. One of my good friends recommended the printer.

Maintenance for the printer consists of swapping out the FEP film on the resin VAT, cleaning out the resin VAT, and leveling the bed. The prints have been very smooth. Removing the supports is the pain part. Doing it before you run it through the curing lamp seems to be easier than post curing. I always wear gloves and a mask when I’m working with the stuff in a ventilated area.

Resin is more expensive than FDM filament but I have found that you can find resin from$25 to $80 depending on the size of the bottle. Also found that for me, the translucent resins have a higher success rate of being able to print objects. I use the fdm printers for a test print for scale and then I will use the resin printer for my final print. I try to print as many objects as I can.

Hope this helps. Let me know if there is anything else

Izzy

Enter your email address to join: