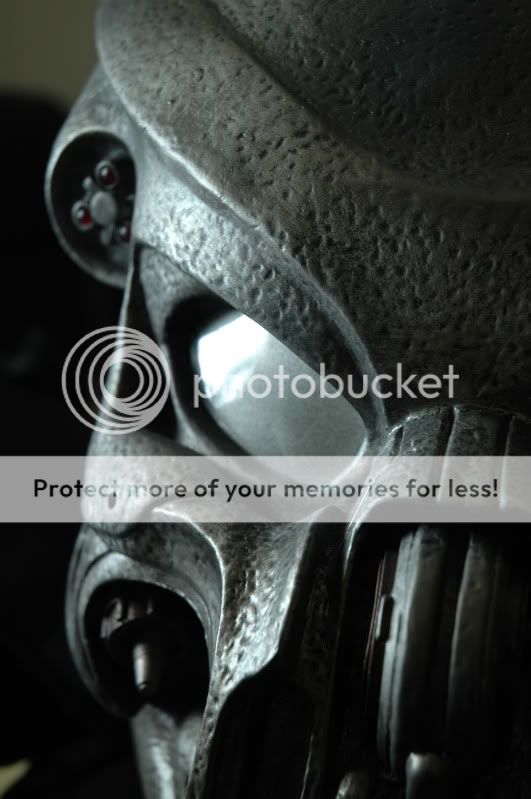

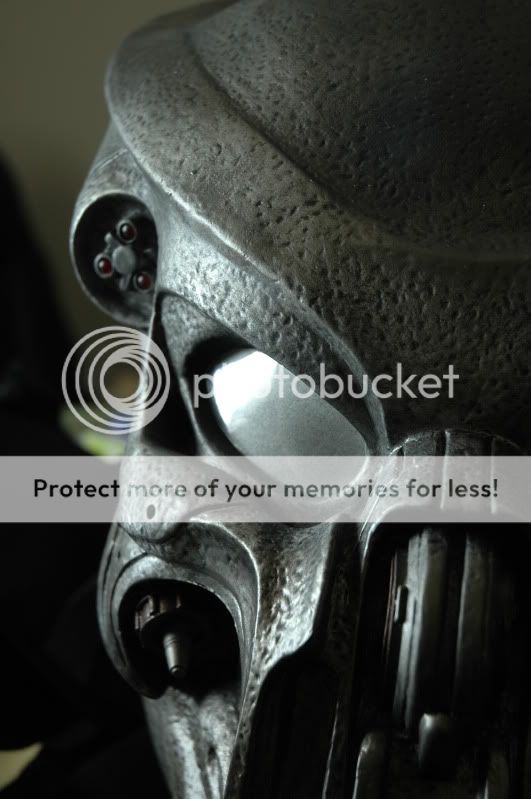

I am still trying to get this all dialed in. The film on there is from a sheet of laminating pouch (typically found at office supplies stores). I ran it through the machine in hot mode with nothing in there, only the pouch. I then trace the eye area with tracing paper, transferred the pattern onto the laminating pouch, and painstaking trim to make an exact fit to the eye area. The only issue I am running into is making it stay down, since the eye area is not complete flat.

I also tried a clear window cling and it works okay. The only issue is the window cling is a lot thinner and does not have the thicker shinnier look to it.

I must add that I am only testing methods that will not do any permenant changes to the origianl condition of the mask. This is why I did not try gluing the lense down.

I have stopped working on it for a couple of days now, as there is a problem area (excessive smoothness in texture compare to the rest of the mask) and a small hole by the nostrile area. I am waiting to hear back from my local dealer and see what SS will do about the problem areas.

agree 100% aswell with what you said about the final product. sideshow seem to be slipping these days

agree 100% aswell with what you said about the final product. sideshow seem to be slipping these days